The tail temperature of wood drying equipment has certa […]

The tail temperature of wood drying equipment has certain specifications. If it is unqualified, the equipment will have an impact on the output power (referring to the amount of work done by the object in a unit time), so our operator needs have an impact , And then know it well, let us introduce some factors that affect the temperature of the tail of the device.

The equipment is related to the increase in fuel and the degree of incineration. Take coal as an example. If the proportion of coal in the differentiation furnace is too high and the incineration is not complete, the coal that is not burned or the pulverized coal that is incompletely burned will fall directly into the drying process. In the body of the equipment, the temperature of the tail will increase. On the contrary, if the coal content is low, the temperature of the tail will decrease.

Poor sealing effect at the end of the equipment. Dryers are classified as mine equipment. Long-term use may cause wear of the tail sealing equipment (a basic type of component failure). The sealing effect is undesirable and air leakage occurs. At this moment, the temperature of the equipment tail must Downward trend.

If the temperature at the end of the wood drying equipment does not meet the standard, the drying effect will be affected at the slightest, and the dry power (referring to how much work the object does in a unit time) and output value will be affected. There are many factors that affect the normality of an equipment. Regardless of the size, we should pay attention to it, this is the maintenance method for the equipment.

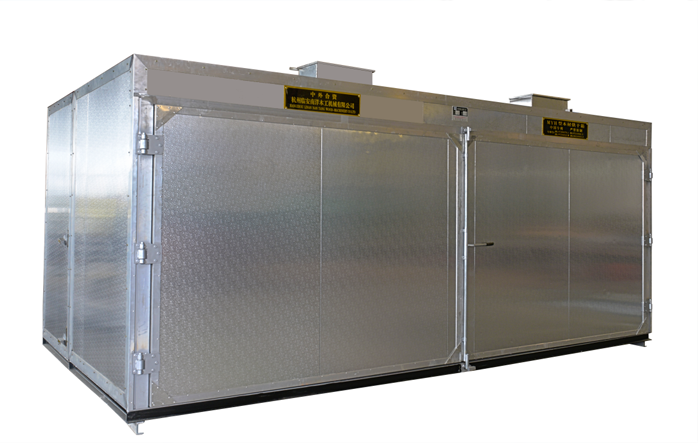

NanYang company has got the R«&D talents of wood drying with rich wood drying experiences. According to the clients’ different scales, products, drying requirements and place conditions, we can make out the best drying solution for our clients to choose most reasonable drying equipments and make you invest half