Products

CONTACT US

- Tel: +86-571-63756938

- Fax: +86-571-63750269

- E-mail: wood991@hzny.com

- Add: 1st Floor, 3rd Block, 1377# Jiuzhou Street, Linglong Subdistrict, Lin'an,Hangzhou, Zhejiang Province China

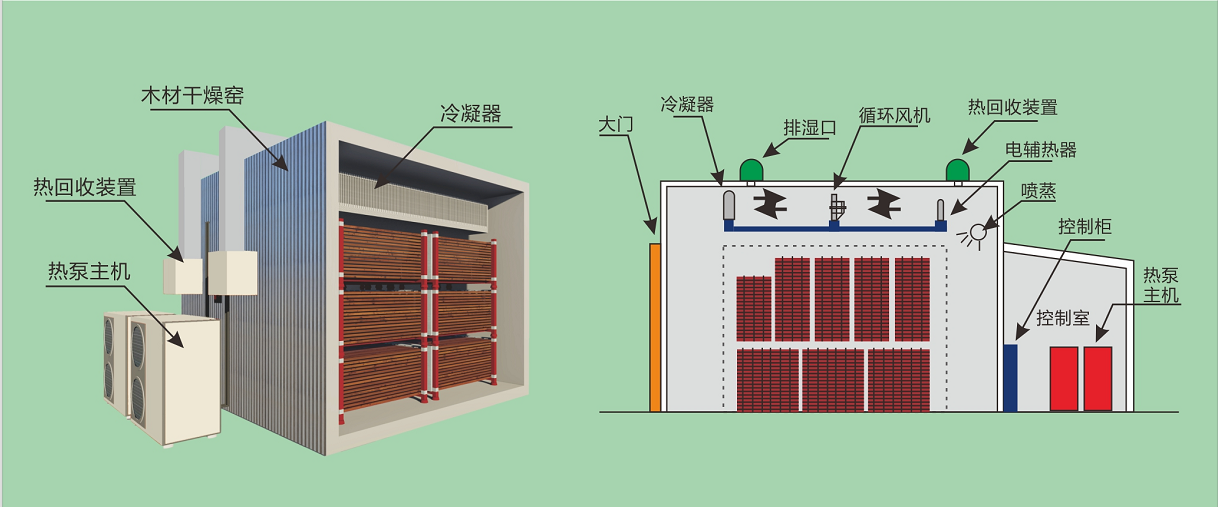

MYHR Heat Pump Wood Drying Kiln

Product Description

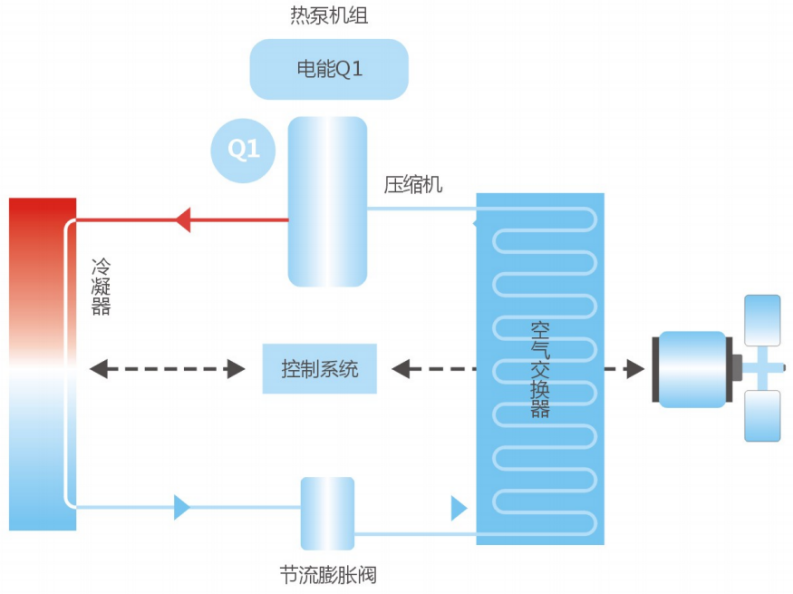

NanYang Heat Pump (Air Energy) wood drying kiln is the new-generation environmental protection & energy conservation drying equipment which is developed and manufactured by our company, with technical support provided by Guangzhou Institute of Energy Conversion of Chinese Academy of Sciences. It adopts the heating mode of air energy heat pumps, supplemented by auxiliary electric heating to carry out drying and heat treatment for wood in winter and at night. The air energy heat pump unit follows the reverse Carnot principle. Freon vapor is pressurized by the compressor, becomes the high temperature & pressure gas, and then enters the condenser. After the condensation and liquefaction by the refrigerant, the high temperature heat is released to implement heating & drying for the air inside the room, so as to achieve the purpose of wood drying and heat treatment.

Details

Product Advantage

- Energy conservation: The system operation efficiency is up to 35%, which is to say that, the proportion of the electric energy input to the heat used for wood drying is 1:3.5.

- Environmental protection: During the process of system operation, have no pollution, with zero emission, meeting the national environmental protection requirements, able to substitute the boiler.

- Simpleness: The installation is simple, with no need of special equipment calibration. The operation is simple, with no need of special equipment operation certificates. The unattended operation may be achieved, to greatly reduce the labor management expense.

- Low operation cost: Due to the high efficiency and energy conservation of the heat pump, the cost is greatly reduced during the wood drying process. Taking the geographical location of Zhejiang as an example, the electricity cost of a heat pump wood drying kiln is equivalent to the cost of steam supply from a firewood boiler.

Technical Parameters:

|

Model |

WFT-KHG15 |

WFT-KHG20 |

WFT-KHG25 |

WFT-KHG30 |

|

Heating Capacity [KW] |

48 |

64 |

72 |

96 |

|

Rated Power[KW] |

13.4 |

16.5 |

22.5 |

23.5 |

|

Rated Current [A] |

20.2 |

24.9 |

34.8 |

35.5 |

|

Maximum Input Power [KW] |

20.1 |

24.75 |

28.5 |

35.25 |

|

Maximum Input Current[A] |

30.5 |

37.6 |

42.8 |

53.6 |

|

Maximum Dewatering Capacity[L/h] |

38 |

58 |

67.5 |

84 |

|

Optimal Air Outlet Temperature |

55 |

55 |

55 |

55 |

|

Maximum Air Outlet Temperature |

75 |

75 |

75 |

75 |

|

Operating Environment Temperature |

-5~43℃ |

|||

|

Power Supply |

380V~50Hz |

|||

|

Refrigerant Type |

Mixing Condensation |

Mixing Condensation |

Mixing Condensation |

Mixing Condensation |

|

Dimension (L*W*H)[mm] |

1510*810*1545 |

2100*910*2020 |

2100*910*2020 |

2100*910*2020 |

|

Host Weight [KG] |

360 |

770 |

850 |

850 |

|

Host Noise [DB(A)] |

≤68 |

≤72 |

≤72 |

≤72 |

Note:

- Operating conditions of above parameters: Ambient dry bulb temperature: 20℃, wet bulb: 15℃, drying room temperature: 50℃, relative humidity: 70% (the dewatering capacity may be tested when the heat recovery unit is configured).

- Operating conditions of heating capacity measurement and test: Environment: 20/15℃ (and -12/-14℃), drying room temperature: 50℃/70%.

General Parameter Configuration Table

|

Scope of Application |

Drying Kiln Space |

M³ |

60以下 |

60~100 |

100~120 |

120~150 |

150~180 |

180~200 |

|

Hard Wood |

Heat Pump Specification & Quantity |

set |

15P×1 |

25P×1 |

15P×2 |

20P×2 |

25P×2 |

30P×2 |

|

Total Heat Pump Power |

KW |

12 |

20 |

24 |

32 |

40 |

48 |

|

|

Quantity of Fans |

只 |

2 |

3 |

4 |

5 |

6 |

8 |

|

|

Auxiliary Electric Heating Power |

KW |

15~30 |

30~60 |

30~60 |

30~60 |

30~90 |

30~90 |

|

|

Total Installed Capacity |

KW |

48 |

89 |

96 |

107 |

148 |

162 |

|

|

Maximum Temperature of Drying Kiln |

℃ |

75 |

||||||

|

Soft Wood |

Heat Pump Specification & Quantity |

M³ |

20P×1 |

15P×2 |

20P×2 |

25P×2 |

30P×2 |

25P×3 |

|

Total Heat Pump Power |

set |

16 |

24 |

32 |

40 |

48 |

60 |

|

|

Quantity of Fans |

KW |

2 |

3 |

4 |

5 |

6 |

8 |

|

|

Auxiliary Electric Heating Power |

set |

15~30 |

30~60 |

30~60 |

30~60 |

30~90 |

30~90 |

|

|

Total Installed Capacity |

KW |

52 |

93 |

104 |

115 |

156 |

174 |

|

|

Maximum Temperature of Drying Kiln |

℃ |

80 |

||||||

Note:

- Heat pump specification & quantity, quantity of fans, and auxiliary electric heating power: In the above table, heat pump specification & quantity, quantity of fans, and auxiliary electric heating power which are matched with the drying kiln in different space are recommended values. The actual values need to be adjusted and determined based on wood drying requirements and geographical difference between south and north.

- Total installed capacity: It is the maximum installed capacity required by the drying kiln when the temperature is below 0℃ in cold winter, the heat pump has the lowest thermal efficiency, and the auxiliary electric heating is fully on.

Recommend

NanYang company has got the R«&D talents of wood drying with rich wood drying experiences. According to the clients’ different scales, products, drying requirements and place conditions, we can make out the best drying solution for our clients to choose most reasonable drying equipments and make you invest half

PRODUCTS

CONTACT US

-

1st Floor, 3rd Block, 1377# Jiuzhou Street,

Linglong Subdistrict, Lin'an,Hangzhou,

Zhejiang Province China - TEL:+(86)-571-63756938 FAX:+(86)-571-63750269

- (Post Code):311301 E-mail:wood991@hzny.com

English

English 简体中文

简体中文 España

España