Products

CONTACT US

- Tel: +86-571-63756938

- Fax: +86-571-63750269

- E-mail: wood991@hzny.com

- Add: 1st Floor, 3rd Block, 1377# Jiuzhou Street, Linglong Subdistrict, Lin'an,Hangzhou, Zhejiang Province China

MYHG Steam Heating Wood Drying Kiln (Aluminum Alloy Structure)

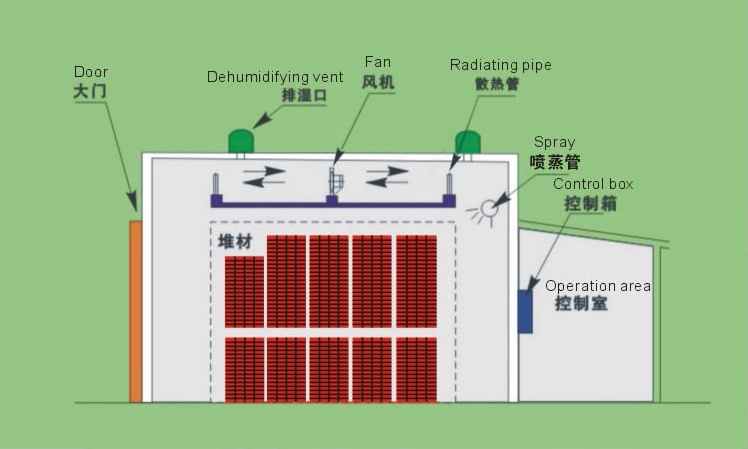

MYHG steam heating wood drying kiln introduce technical processes of advanced drying equipment of Germany and Italy. They have advanced and flexible controlling methods and they are easy for operation. The controlling precision of temperature, humidity and water content rate are high. They have low power consumption. Drying quality is good and without pollution.

Drying kiln control system: Full automatic computer control & semi-automatic control.

Details

Aluminum alloy structure configuration:

- Aluminum alloy shell, stainless steel joint bolts

- Stainless steel tubes are used for internal pipelines for drying kiln.

- Bimetal composite radiating pipes are used for radiator. The base tubes are made of stainless steel.

- High temperature and high humidity durable motors, Aluminum alloy casting impellers and frames are used for recycle fan.

- Originally imported electric heating valves, spraying steamelectromagnetism valves and dehumidifying

- Imported controlling instruments and the sensors.

Technical Parameters:

|

Type |

Volume In theory(M3) |

Piling Wood Size (W×L×H)mm |

Internal Kiln Size (W×L×H)mm |

Motor QTY. |

Total power(kw) |

Fan Type |

Heat source |

|

Aluminum alloy structure |

|||||||

|

MYHG-60 |

30 |

4000×3600×4400 |

4400×5000×5500 |

2 |

6 |

φ800 |

Steam |

|

MYHG-80 |

40 |

4000×4600×4400 |

4400×6200×5500 |

2 |

6 |

||

|

MYHG-100 |

50 |

6000×3800×4400 |

6400×5000×5500 |

3 |

9 |

||

|

MYHG-120 |

60 |

6000×4600×4400 |

6400×6200×5500 |

3 |

9 |

||

|

MYHG-160 |

80 |

8000×4600×4400 |

8400×6200×5500 |

4 |

12 |

||

|

MYHG-200 |

100 |

8000×6000×4400 |

8400×8000×5500 |

5 |

15 |

||

|

MYHG-240 |

120 |

10000×6000×4400 |

10500×8000×5500 |

6 |

18 |

||

|

MYHG-300 |

150 |

12000×6000×4400 |

12600×8000×5500 |

8 |

24 |

||

|

MYHG-400 |

200 |

12000×7000×4400 |

12600×9200×6100 |

10 |

30 |

||

The schematic drawing of drying wood:

Recommend

NanYang company has got the R«&D talents of wood drying with rich wood drying experiences. According to the clients’ different scales, products, drying requirements and place conditions, we can make out the best drying solution for our clients to choose most reasonable drying equipments and make you invest half

PRODUCTS

CONTACT US

-

1st Floor, 3rd Block, 1377# Jiuzhou Street,

Linglong Subdistrict, Lin'an,Hangzhou,

Zhejiang Province China - TEL:+(86)-571-63756938 FAX:+(86)-571-63750269

- (Post Code):311301 E-mail:wood991@hzny.com

English

English 简体中文

简体中文 España

España